RUITE

RUITE

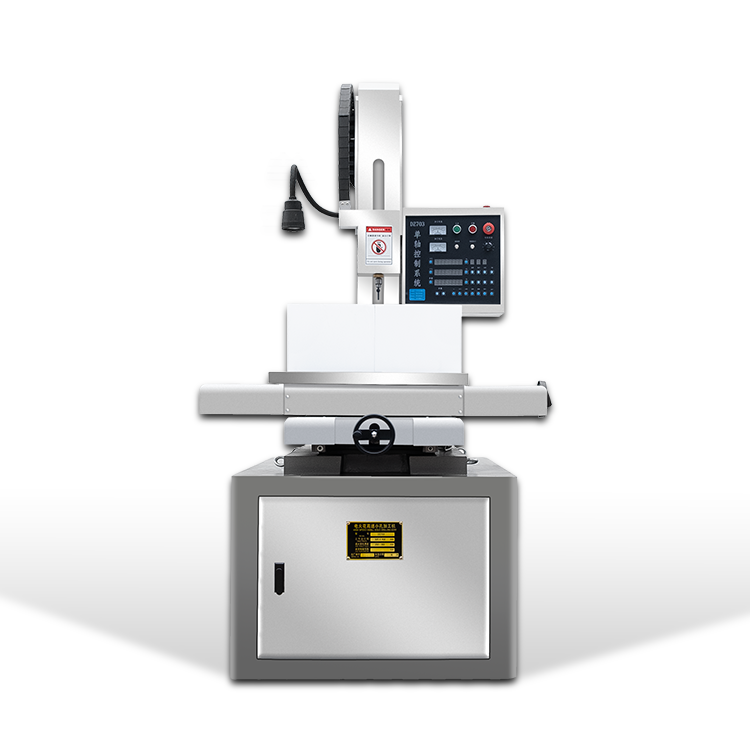

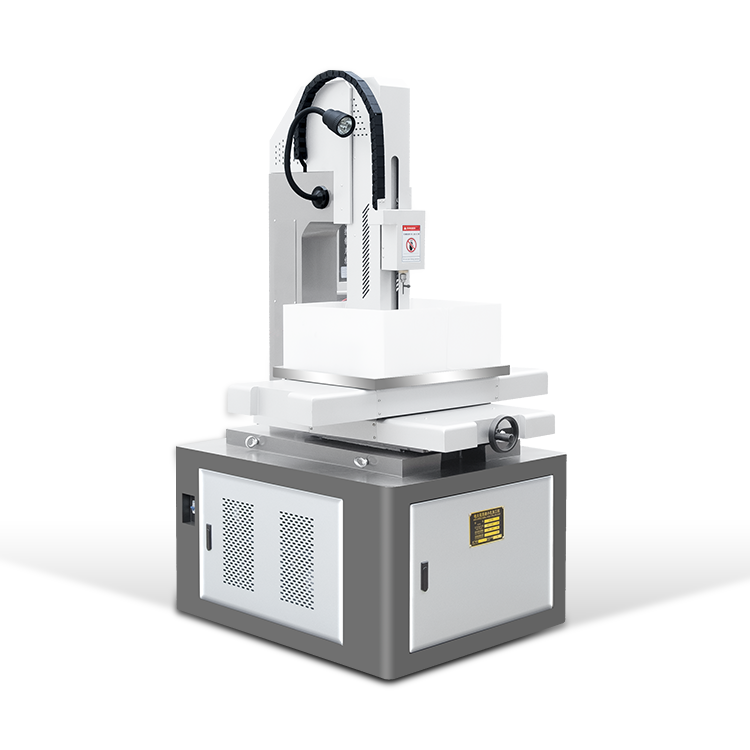

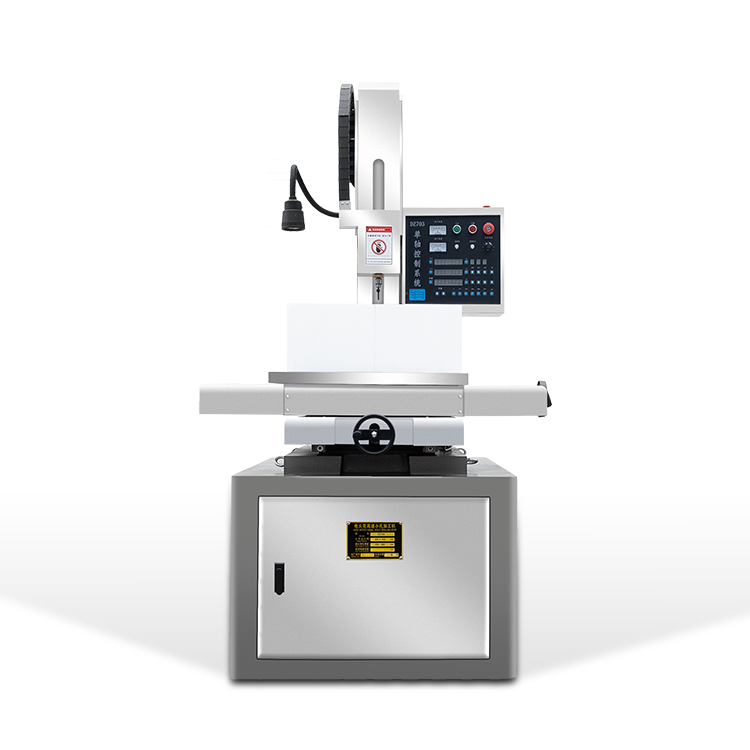

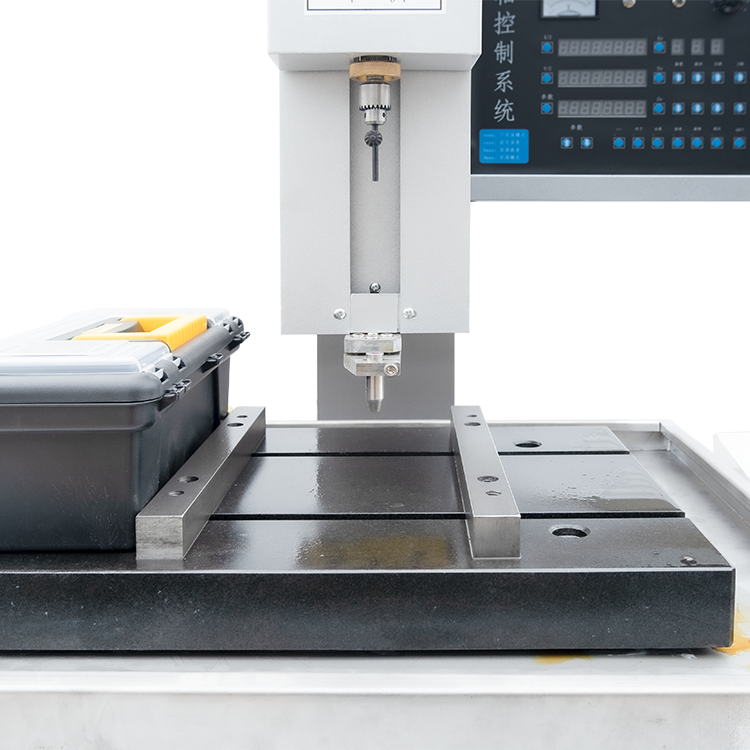

The EDM drilling machine is mainly used for drilling deep and small holes in various kinds of conducting materials such as stainless steel, hardened steel, hard alloy, copper and aluminium. It can make holes for EDM wire cutting machine wire, spinneret orifice of chemical fiber spinneret, holes in filter plates and sieve plates, ventilation holes of engine blade and cylinder block, pipelines and pneumatic holes of hydraulic and pneumatic valves.

The EDM drilling machine is mainly used for drilling deep and small holes in various kinds of conducting materials such as stainless steel, hardened steel, hard alloy, copper and aluminium. It can make holes for EDM wire cutting machine wire, spinneret orifice of chemical fiber spinneret, holes in filter plates and sieve plates, ventilation holes of engine blade and cylinder block, pipelines and pneumatic holes of hydraulic and pneumatic valves.

The EDM drilling machine is mainly used for drilling deep and small holes in various kinds of conducting materials such as stainless steel, hardened steel, hard alloy, copper and aluminium. It can make holes for EDM wire cutting machine wire, spinneret orifice of chemical fiber spinneret, holes in filter plates and sieve plates, ventilation holes of engine blade and cylinder block, pipelines and pneumatic holes of hydraulic and pneumatic valves.

The EDM drilling machine is mainly used for drilling deep and small holes in various kinds of conducting materials such as stainless steel, hardened steel, hard alloy, copper and aluminium. It can make holes for EDM wire cutting machine wire, spinneret orifice of chemical fiber spinneret, holes in filter plates and sieve plates, ventilation holes of engine blade and cylinder block, pipelines and pneumatic holes of hydraulic and pneumatic valves.

The EDM drilling machine is mainly used for drilling deep and small holes in various kinds of conducting materials such as stainless steel, hardened steel, hard alloy, copper and aluminium. It can make holes for EDM wire cutting machine wire, spinneret orifice of chemical fiber spinneret, holes in filter plates and sieve plates, ventilation holes of engine blade and cylinder block, pipelines and pneumatic holes of hydraulic and pneumatic valves.

The EDM drilling machine is mainly used for drilling deep and small holes in various kinds of conducting materials such as stainless steel, hardened steel, hard alloy, copper and aluminium. It can make holes for EDM wire cutting machine wire, spinneret orifice of chemical fiber spinneret, holes in filter plates and sieve plates, ventilation holes of engine blade and cylinder block, pipelines and pneumatic holes of hydraulic and pneumatic valves.

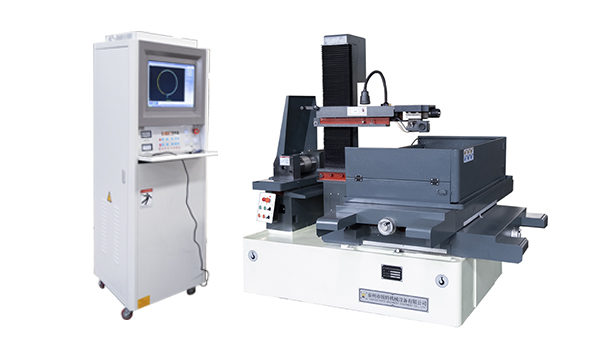

Taizhou Ruite Machinery Equipment Co., Ltd. produces whole series of DK77 CNC edm wire cutting machines,which adopts high precision V-shaped guide rail(Linear guide rail optional) and P3-grade high precison ball screw. The products have high quality, complete models, long service life and high precision. Machine specifications can be customized according to customer needs,like non-standard models DK7740(45)F,DK7750(55)F,DK7763F,DK7780F,DK77100F,DK77120F or even larger models. The company also produces ±30°, ±45° swing large taper machines and CNC high-precision middle speed edm wire cutting machines(Precision≤±0.005mm,roughness≤1.0μm). The following are the main parameters of DK77 series machines: 1.Standard maximum cutting taper:±6°/80mm;(±15°,±30°,±45° are optional) 2.Precision ≤ 0.02mm,according to GB7926-2005 standard;(If linear guide equipped, the precision can reach 0.01mm) 3.Best surface roughness ≤ Ra2.5μm(single-cut),Ra1.5μm(multi-cut); 4.Molybdenum wire diameter:0.1-0.2mm; 5.Max. cutting speed≥120mm^2/min; 6.Voltage:3 phase 380V(single phase 220V,3 phase 220V or other voltage can be customized),Power:1.5KW; 7.Working fluid:Water-based emulsion.

Taizhou Ruite Machinery Equipment Co., Ltd. produces whole series of DK77 CNC edm wire cutting machines,which adopts high precision V-shaped guide rail(Linear guide rail optional) and P3-grade high precison ball screw. The products have high quality, complete models, long service life and high precision. Machine specifications can be customized according to customer needs,like non-standard models DK7740(45)F,DK7750(55)F,DK7763F,DK7780F,DK77100F,DK77120F or even larger models. The company also produces ±30°, ±45° swing large taper machines and CNC high-precision middle speed edm wire cutting machines(Precision≤±0.005mm,roughness≤1.0μm). The following are the main parameters of DK77 series machines: 1.Standard maximum cutting taper:±6°/80mm;(±15°,±30°,±45° are optional) 2.Precision ≤ 0.02mm,according to GB7926-2005 standard;(If linear guide equipped, the precision can reach 0.01mm) 3.Best surface roughness ≤ Ra2.5μm(single-cut),Ra1.5μm(multi-cut); 4.Molybdenum wire diameter:0.1-0.2mm; 5.Max. cutting speed≥120mm^2/min; 6.Voltage:3 phase 380V(single phase 220V,3 phase 220V or other voltage can be customized),Power:1.5KW; 7.Working fluid:Water-based emulsion.

Taizhou Ruite Machinery Equipment Co., Ltd. produces whole series of DK77 CNC edm wire cutting machines,which adopts high precision V-shaped guide rail(Linear guide rail optional) and P3-grade high precison ball screw. The products have high quality, complete models, long service life and high precision. Machine specifications can be customized according to customer needs,like non-standard models DK7740(45)F,DK7750(55)F,DK7763F,DK7780F,DK77100F,DK77120F or even larger models. The company also produces ±30°, ±45° swing large taper machines and CNC high-precision middle speed edm wire cutting machines(Precision≤±0.005mm,roughness≤1.0μm). The following are the main parameters of DK77 series machines: 1.Standard maximum cutting taper:±6°/80mm;(±15°,±30°,±45° are optional) 2.Precision ≤ 0.02mm,according to GB7926-2005 standard;(If linear guide equipped, the precision can reach 0.01mm) 3.Best surface roughness ≤ Ra2.5μm(single-cut),Ra1.5μm(multi-cut); 4.Molybdenum wire diameter:0.1-0.2mm; 5.Max. cutting speed≥120mm^2/min; 6.Voltage:3 phase 380V(single phase 220V,3 phase 220V or other voltage can be customized),Power:1.5KW; 7.Working fluid:Water-based emulsion.

Taizhou Ruite Machinery Equipment Co., Ltd. produces whole series of DK77 CNC edm wire cutting machines,which adopts high precision V-shaped guide rail(Linear guide rail optional) and P3-grade high precison ball screw. The products have high quality, complete models, long service life and high precision. Machine specifications can be customized according to customer needs,like non-standard models DK7740(45)F,DK7750(55)F,DK7763F,DK7780F,DK77100F,DK77120F or even larger models. The company also produces ±30°, ±45° swing large taper machines and CNC high-precision middle speed edm wire cutting machines(Precision≤±0.005mm,roughness≤1.0μm). The following are the main parameters of DK77 series machines: 1.Standard maximum cutting taper:±6°/80mm;(±15°,±30°,±45° are optional) 2.Precision ≤ 0.02mm,according to GB7926-2005 standard;(If linear guide equipped, the precision can reach 0.01mm) 3.Best surface roughness ≤ Ra2.5μm(single-cut),Ra1.5μm(multi-cut); 4.Molybdenum wire diameter:0.1-0.2mm; 5.Max. cutting speed≥120mm^2/min; 6.Voltage:3 phase 380V(single phase 220V,3 phase 220V or other voltage can be customized),Power:1.5KW; 7.Working fluid:Water-based emulsion.

Taizhou Ruite Machinery Equipment Co., Ltd. produces whole series of DK77 CNC edm wire cutting machines,which adopts high precision V-shaped guide rail(Linear guide rail optional) and P3-grade high precison ball screw. The products have high quality, complete models, long service life and high precision. Machine specifications can be customized according to customer needs,like non-standard models DK7740(45)F,DK7750(55)F,DK7763F,DK7780F,DK77100F,DK77120F or even larger models. The company also produces ±30°, ±45° swing large taper machines and CNC high-precision middle speed edm wire cutting machines(Precision≤±0.005mm,roughness≤1.0μm). The following are the main parameters of DK77 series machines: 1.Standard maximum cutting taper:±6°/80mm;(±15°,±30°,±45° are optional) 2.Precision ≤ 0.02mm,according to GB7926-2005 standard;(If linear guide equipped, the precision can reach 0.01mm) 3.Best surface roughness ≤ Ra2.5μm(single-cut),Ra1.5μm(multi-cut); 4.Molybdenum wire diameter:0.1-0.2mm; 5.Max. cutting speed≥120mm^2/min; 6.Voltage:3 phase 380V(single phase 220V,3 phase 220V or other voltage can be customized),Power:1.5KW; 7.Working fluid:Water-based emulsion.

Taizhou Ruite Machinery Equipment Co., Ltd. produces whole series of DK77 CNC edm wire cutting machines,which adopts high precision V-shaped guide rail(Linear guide rail optional) and P3-grade high precison ball screw. The products have high quality, complete models, long service life and high precision. Machine specifications can be customized according to customer needs,like non-standard models DK7740(45)F,DK7750(55)F,DK7763F,DK7780F,DK77100F,DK77120F or even larger models. The company also produces ±30°, ±45° swing large taper machines and CNC high-precision middle speed edm wire cutting machines(Precision≤±0.005mm,roughness≤1.0μm). The following are the main parameters of DK77 series machines: 1.Standard maximum cutting taper:±6°/80mm;(±15°,±30°,±45° are optional) 2.Precision ≤ 0.02mm,according to GB7926-2005 standard;(If linear guide equipped, the precision can reach 0.01mm) 3.Best surface roughness ≤ Ra2.5μm(single-cut),Ra1.5μm(multi-cut); 4.Molybdenum wire diameter:0.1-0.2mm; 5.Max. cutting speed≥120mm^2/min; 6.Voltage:3 phase 380V(single phase 220V,3 phase 220V or other voltage can be customized),Power:1.5KW; 7.Working fluid:Water-based emulsion.

Vertical Machining Center Greatly improved processing efficiency Imported bearings / Quenching castings / Taiwan tool magazine

Vertical Machining Center Greatly improved processing efficiency Imported bearings / Quenching castings / Taiwan tool magazine

Vertical Machining Center Greatly improved processing efficiency Imported bearings / Quenching castings / Taiwan tool magazine

Vertical Machining Center Greatly improved processing efficiency Imported bearings / Quenching castings / Taiwan tool magazine

Vertical Machining Center Greatly improved processing efficiency Imported bearings / Quenching castings / Taiwan tool magazine

Vertical Machining Center Greatly improved processing efficiency Imported bearings / Quenching castings / Taiwan tool magazine

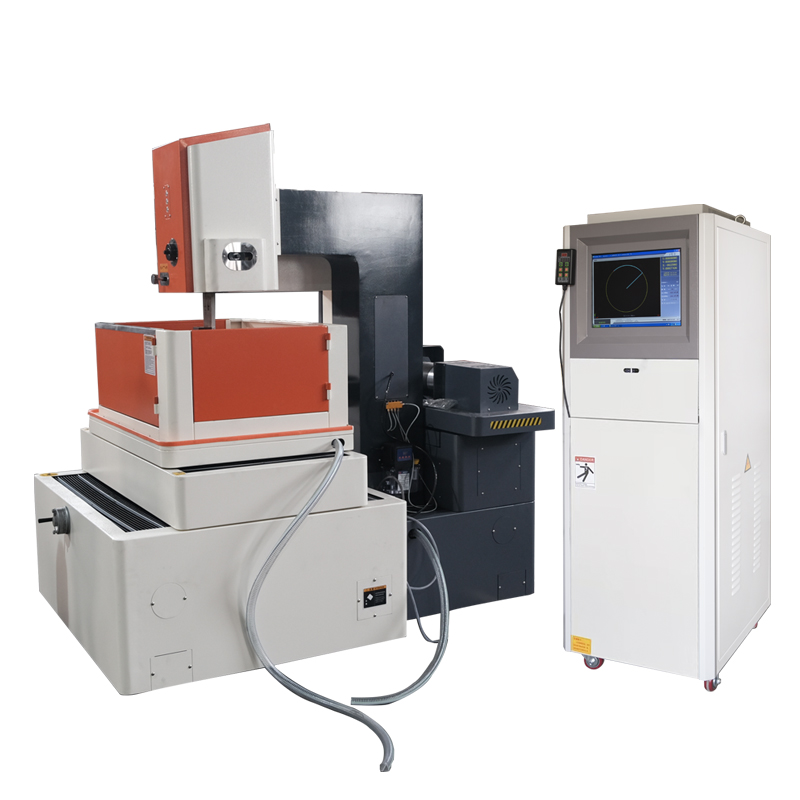

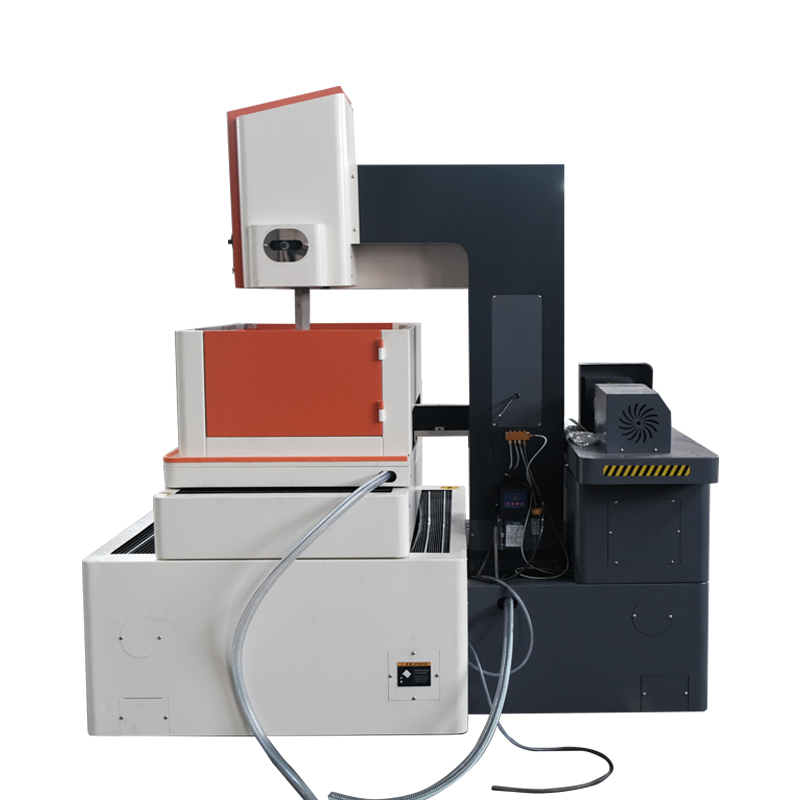

Because brass wire cutting machine tools are expensive and difficult to learn, Taizhou Ruite Machinery Equipment Co.,Ltd. has continuously improved our RT series machines based on the strengths of hundreds of the companies,which is with simple operation,long service life and high cost performance. Molybdenum wire can be reused instead of disposable brass wire.Not only greatly reduces the cost of buying machines and processing for customers, but also provides customers with excellent cutting prcision and finish. The machine parts all come from high-end brands (HIWIN linear guide rail, Japan NSK bearings, Military grade P3 double nut ball screw, Japan Panasonic servo system, etc.) to ensure good machine performance, and at the same time,we still provide customers with reasonable price. The company also produces ±30°, ±45° swing large taper machines and CNC high-precision middle speed edm wire cutting machines(Precision≤±0.005mm,roughness≤1.0μm). The following are the main parameters of DK77 series machines: 1.Standard maximum cutting taper:±6°/80mm;(±15°,±30°,±45° are optional) 2.Precision ≤ 0.02mm,according to GB7926-2005 standard;(If linear guide equipped, the precision can reach 0.01mm) 3.Best surface roughness ≤ Ra2.5μm(single-cut),Ra1.5μm(multi-cut); 4.Molybdenum wire diameter:0.1-0.2mm; 5.Max. cutting speed≥120mm^2/min; 6.Voltage:3 phase 380V(single phase 220V,3 phase 220V or other voltage can be customized),Power:1.5KW; 7.Working fluid:Water-based emulsion.

Because brass wire cutting machine tools are expensive and difficult to learn, Taizhou Ruite Machinery Equipment Co.,Ltd. has continuously improved our RT series machines based on the strengths of hundreds of the companies,which is with simple operation,long service life and high cost performance. Molybdenum wire can be reused instead of disposable brass wire.Not only greatly reduces the cost of buying machines and processing for customers, but also provides customers with excellent cutting prcision and finish. The machine parts all come from high-end brands (HIWIN linear guide rail, Japan NSK bearings, Military grade P3 double nut ball screw, Japan Panasonic servo system, etc.) to ensure good machine performance, and at the same time,we still provide customers with reasonable price. The company also produces ±30°, ±45° swing large taper machines and CNC high-precision middle speed edm wire cutting machines(Precision≤±0.005mm,roughness≤1.0μm). The following are the main parameters of DK77 series machines: 1.Standard maximum cutting taper:±6°/80mm;(±15°,±30°,±45° are optional) 2.Precision ≤ 0.02mm,according to GB7926-2005 standard;(If linear guide equipped, the precision can reach 0.01mm) 3.Best surface roughness ≤ Ra2.5μm(single-cut),Ra1.5μm(multi-cut); 4.Molybdenum wire diameter:0.1-0.2mm; 5.Max. cutting speed≥120mm^2/min; 6.Voltage:3 phase 380V(single phase 220V,3 phase 220V or other voltage can be customized),Power:1.5KW; 7.Working fluid:Water-based emulsion.

Because brass wire cutting machine tools are expensive and difficult to learn, Taizhou Ruite Machinery Equipment Co.,Ltd. has continuously improved our RT series machines based on the strengths of hundreds of the companies,which is with simple operation,long service life and high cost performance. Molybdenum wire can be reused instead of disposable brass wire.Not only greatly reduces the cost of buying machines and processing for customers, but also provides customers with excellent cutting prcision and finish. The machine parts all come from high-end brands (HIWIN linear guide rail, Japan NSK bearings, Military grade P3 double nut ball screw, Japan Panasonic servo system, etc.) to ensure good machine performance, and at the same time,we still provide customers with reasonable price. The company also produces ±30°, ±45° swing large taper machines and CNC high-precision middle speed edm wire cutting machines(Precision≤±0.005mm,roughness≤1.0μm). The following are the main parameters of DK77 series machines: 1.Standard maximum cutting taper:±6°/80mm;(±15°,±30°,±45° are optional) 2.Precision ≤ 0.02mm,according to GB7926-2005 standard;(If linear guide equipped, the precision can reach 0.01mm) 3.Best surface roughness ≤ Ra2.5μm(single-cut),Ra1.5μm(multi-cut); 4.Molybdenum wire diameter:0.1-0.2mm; 5.Max. cutting speed≥120mm^2/min; 6.Voltage:3 phase 380V(single phase 220V,3 phase 220V or other voltage can be customized),Power:1.5KW; 7.Working fluid:Water-based emulsion.

Because brass wire cutting machine tools are expensive and difficult to learn, Taizhou Ruite Machinery Equipment Co.,Ltd. has continuously improved our RT series machines based on the strengths of hundreds of the companies,which is with simple operation,long service life and high cost performance. Molybdenum wire can be reused instead of disposable brass wire.Not only greatly reduces the cost of buying machines and processing for customers, but also provides customers with excellent cutting prcision and finish. The machine parts all come from high-end brands (HIWIN linear guide rail, Japan NSK bearings, Military grade P3 double nut ball screw, Japan Panasonic servo system, etc.) to ensure good machine performance, and at the same time,we still provide customers with reasonable price. The company also produces ±30°, ±45° swing large taper machines and CNC high-precision middle speed edm wire cutting machines(Precision≤±0.005mm,roughness≤1.0μm). The following are the main parameters of DK77 series machines: 1.Standard maximum cutting taper:±6°/80mm;(±15°,±30°,±45° are optional) 2.Precision ≤ 0.02mm,according to GB7926-2005 standard;(If linear guide equipped, the precision can reach 0.01mm) 3.Best surface roughness ≤ Ra2.5μm(single-cut),Ra1.5μm(multi-cut); 4.Molybdenum wire diameter:0.1-0.2mm; 5.Max. cutting speed≥120mm^2/min; 6.Voltage:3 phase 380V(single phase 220V,3 phase 220V or other voltage can be customized),Power:1.5KW; 7.Working fluid:Water-based emulsion.

Because brass wire cutting machine tools are expensive and difficult to learn, Taizhou Ruite Machinery Equipment Co.,Ltd. has continuously improved our RT series machines based on the strengths of hundreds of the companies,which is with simple operation,long service life and high cost performance. Molybdenum wire can be reused instead of disposable brass wire.Not only greatly reduces the cost of buying machines and processing for customers, but also provides customers with excellent cutting prcision and finish. The machine parts all come from high-end brands (HIWIN linear guide rail, Japan NSK bearings, Military grade P3 double nut ball screw, Japan Panasonic servo system, etc.) to ensure good machine performance, and at the same time,we still provide customers with reasonable price. The company also produces ±30°, ±45° swing large taper machines and CNC high-precision middle speed edm wire cutting machines(Precision≤±0.005mm,roughness≤1.0μm). The following are the main parameters of DK77 series machines: 1.Standard maximum cutting taper:±6°/80mm;(±15°,±30°,±45° are optional) 2.Precision ≤ 0.02mm,according to GB7926-2005 standard;(If linear guide equipped, the precision can reach 0.01mm) 3.Best surface roughness ≤ Ra2.5μm(single-cut),Ra1.5μm(multi-cut); 4.Molybdenum wire diameter:0.1-0.2mm; 5.Max. cutting speed≥120mm^2/min; 6.Voltage:3 phase 380V(single phase 220V,3 phase 220V or other voltage can be customized),Power:1.5KW; 7.Working fluid:Water-based emulsion.

Because brass wire cutting machine tools are expensive and difficult to learn, Taizhou Ruite Machinery Equipment Co.,Ltd. has continuously improved our RT series machines based on the strengths of hundreds of the companies,which is with simple operation,long service life and high cost performance. Molybdenum wire can be reused instead of disposable brass wire.Not only greatly reduces the cost of buying machines and processing for customers, but also provides customers with excellent cutting prcision and finish. The machine parts all come from high-end brands (HIWIN linear guide rail, Japan NSK bearings, Military grade P3 double nut ball screw, Japan Panasonic servo system, etc.) to ensure good machine performance, and at the same time,we still provide customers with reasonable price. The company also produces ±30°, ±45° swing large taper machines and CNC high-precision middle speed edm wire cutting machines(Precision≤±0.005mm,roughness≤1.0μm). The following are the main parameters of DK77 series machines: 1.Standard maximum cutting taper:±6°/80mm;(±15°,±30°,±45° are optional) 2.Precision ≤ 0.02mm,according to GB7926-2005 standard;(If linear guide equipped, the precision can reach 0.01mm) 3.Best surface roughness ≤ Ra2.5μm(single-cut),Ra1.5μm(multi-cut); 4.Molybdenum wire diameter:0.1-0.2mm; 5.Max. cutting speed≥120mm^2/min; 6.Voltage:3 phase 380V(single phase 220V,3 phase 220V or other voltage can be customized),Power:1.5KW; 7.Working fluid:Water-based emulsion.

Manufacturing

Manufacturing Founded

Professional Worker

Countries Worldwide

Successful Project